When your LED sheet stops responding to remote commands, it can be frustrating. The problem often comes from signal interference, power issues, or mismatched components. This guide covers testing methods—like multimeter checks and protocol analysis—to help you find and fix the issue quickly. Whether it’s infrared (IR) interference or radio frequency (RF) signal dropout, understanding the causes helps keep your professional lighting setup working smoothly.

Why Is My LED Sheet Not Responding to the Remote?

If your LED sheet with remote isn’t working, you’re not alone. This issue happens a lot, especially in places with spotty signals or uneven power. Whether you’re using Flexible LED Sheet, Programmable LED Sheet, or Hybrid LED Sheet models, finding the problem takes a step-by-step approach and some know-how about hardware and signals.

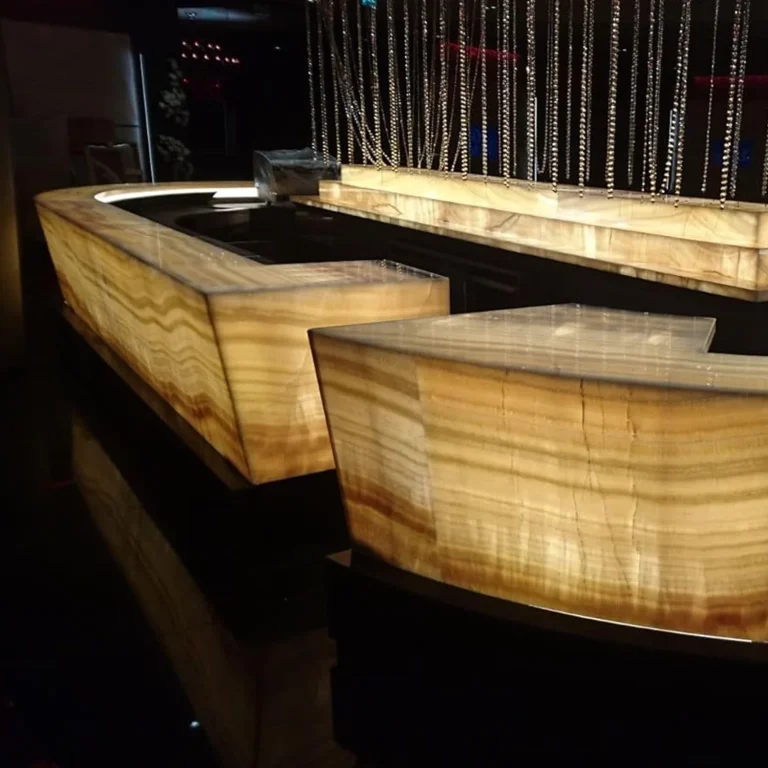

Before we start troubleshooting, let’s talk about a trusted brand in lighting technology. For high-quality lighting solutions for buildings or businesses, check out RAYMATES’ Lensed LED Sheet. This product line is built with precision and great light control—perfect for pros who need reliable light spread and remote response. RAYMATES also offers Flexible LED Sheet, Programmable LED Sheet, and Interactive LED Light Sheet models for various needs.

What Are the Most Common Reasons Your Remote-Controlled LED Sheet Fails?

Could Environmental Interference or Signal Obstacles Be Disrupting Transmission?

Signal interference is a big reason remotes fail. IR remotes need a clear path between the remote and the LED sheet’s receiver. Things like furniture, walls, or shiny surfaces can weaken the signal. For example, a couch or a mirror might block or reflect the IR light, making it hard for the receiver to pick it up.

RF remotes don’t need a direct line of sight. However, they can be messed up by electromagnetic interference (EMI). Nearby Wi-Fi routers, microwaves, or heavy machinery can cause problems. In setups with LED Downlight Sheet or ceiling-mounted units, EMI from air conditioning systems can also make the remote less responsive.

Have You Checked Battery Levels and Power Supply Consistency?

A weak battery in your remote can send spotty signals. This means the LED sheet might not respond. Also, if the power going to the LED sheet is unsteady, the receiver might not work right. If your setup has a dimmable driver or transformer, make sure it matches the voltage needs of your model.

RAYMATES’ Lensed LED Sheet has built-in circuits to handle power changes. But not all systems have this feature, so double-check your power setup.

Are You Using an IR Remote with an RF-Only Receiver—or Vice Versa?

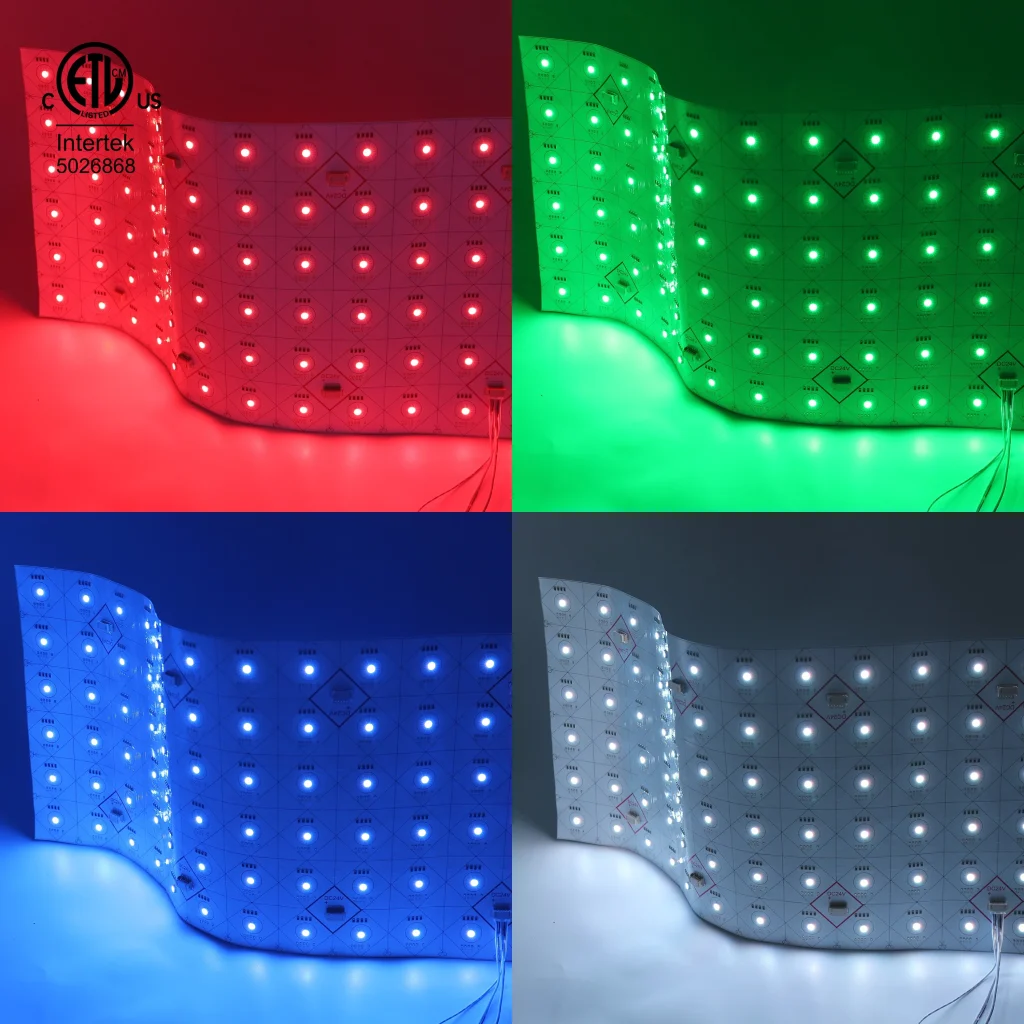

Mixing up remote types is a common mistake. IR remotes use light waves at 38kHz. RF remotes use radio waves, like 433MHz or 2.4GHz. If your LED sheet has an RF receiver but you’re using an IR remote, it won’t work. The same goes for using an RF remote with an IR receiver. Always check the specs to make sure they match.

Which Diagnostic Tools Can Help Identify the Problem?

How Can a Multimeter Be Used to Confirm Power Continuity Across Circuits?

A digital multimeter is a must-have tool. It checks if power is reaching key parts of your LED sheet’s circuit board. Test the voltage at the power supply and receiver module inputs. If the voltage drops suddenly, there might be a broken wire or a bad capacitor. This is super helpful for LED Paper-Like Sheet models, where thin materials can get damaged easily during handling.

To use a multimeter, set it to DC voltage mode. Connect the probes to the circuit’s input points. A steady reading means power is flowing. If the reading jumps or is zero, you’ve got a problem to fix.

What Can Oscilloscopes Reveal About Signal Integrity Between Remote and Receiver?

Oscilloscopes show you what’s happening with signals in real time. Connect the oscilloscope probe to the receiver’s input pin. Then press buttons on the remote. You should see clean square waves with steady timing and strength. If the waves look messy, it could mean bad solder joints or interference from the circuit board’s layout.

This method helps spot issues like distorted signals, which can stop the LED sheet from responding properly.

Why Use Spectrum Analyzers When Diagnosing RF-Controlled Systems?

For RF systems using 433MHz or 2.4GHz, spectrum analyzers check if signals are reaching the receiver without interference. They show if other devices, like Wi-Fi routers, are crowding the same frequency band. This is key for setups with Hybrid LED Sheet networks in big spaces, where multiple control zones might overlap.

A spectrum analyzer can spot unwanted signals or noise. This helps you figure out if external devices are causing RF signal dropout.

Could Issues Originate From Inside the Integrated Receiver Module?

How Do You Identify Technical Specs of Receiver Modules Embedded in Advanced Lighting Sheets?

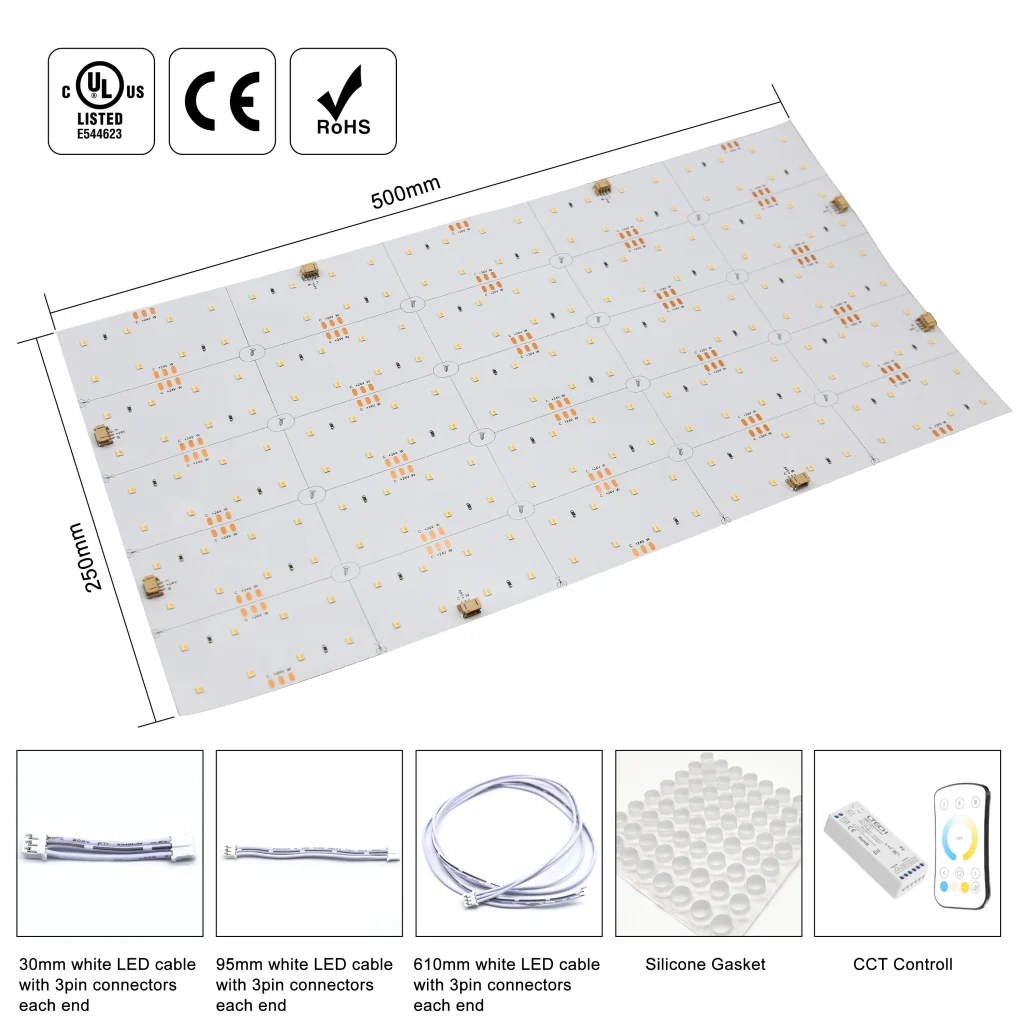

Start by finding the datasheet for your LED sheet model. Many smart lighting sheets, like Programmable LED Sheets, use receivers with microcontrollers. These support features like PWM dimming or multi-channel control. Check if the receiver is IR- or RF-compatible and its voltage range. This info is critical before swapping out parts.

RAYMATES provides detailed specs for their products, which makes this step easier. Look for model numbers on the circuit board or in the user manual.

What Happens When Input Voltage Is Present but No Response Occurs?

If the receiver gets steady voltage but doesn’t respond when you press the remote, the microcontroller unit (MCU) might be damaged. Sometimes, static electricity from handling can mess up the MCU’s memory. If the receiver has a reset pin, try using it to reboot the system. This might fix the issue without replacing parts.

If that doesn’t work, the receiver module might need to be replaced. Check with RAYMATES for compatible replacements to avoid further issues.

Is Protocol-Level Testing Necessary When Everything Else Looks Fine?

How Do You Decode Infrared Communication Protocols Used in Lighting Controls?

To check IR protocols, use a photodiode sensor and a logic analyzer. Connect them to IR decoding software to capture the signals sent by your remote. Common protocols include NEC, RC5, or custom ones made by the manufacturer. If the remote’s protocol doesn’t match what the receiver expects, the LED sheet won’t respond, even if the signal looks fine electrically.

For example, press a button on the remote and watch the logic analyzer. It should show a clear pattern of pulses. If the pattern doesn’t match the receiver’s protocol, you’ve found the problem.

Can Frequency Mismatch Prevent Successful Communication Between Controller and Lighting Unit?

Yes, frequency mismatches cause big issues. If your remote sends signals at 315MHz but the receiver expects 433MHz, they won’t connect. Check the frequency ratings on the circuit board or in the datasheet. This is especially important for RF-based systems, where mismatched frequencies are a common reason for failure.

Could Circuit Layout Be Affecting Signal Responsiveness?

What Role Does PCB Design Play in Signal Transmission Efficiency Across Lighting Modules?

The way traces are laid out on a circuit board affects how well signals travel. In systems like Interactive LED Light Sheets, high-speed signals for dimming or control need clean paths. Badly routed traces can slow down signals or cause timing issues in the microcontroller. This can make the LED sheet ignore remote commands.

Good PCB design keeps traces short and avoids crossing noisy power lines. This ensures signals stay strong and clear.

Are Shielding Practices Sufficient for High-Frequency Applications Within Your Setup?

To block interference, use solid ground planes under high-speed traces. Add shielding covers around sensitive chips to protect against noise from motors or other devices. This is super important in industrial settings, where heavy equipment can create electromagnetic fields that mess with RF signals.

For example, in a factory with lots of machines, shielding keeps your LED sheet’s receiver from picking up stray signals.

Which Solutions Are Recommended for Long-Term Stability and Sensitivity?

What Features Make Certain Remote-Controlled Lighting Sheets More Reliable Than Others?

Choose LED sheets with built-in EMI filters on signal lines. Look for watchdog timers in microcontrollers to fix software glitches automatically. Surge-protected power inputs are also a must. RAYMATES’ LED Sheets often include thermal sensors to adjust brightness based on heat, which keeps performance steady over time.

These features make professional-grade lighting systems, like those used in buildings, more dependable.

How Can You Prevent Future Failures During Installation and Use?

Where Should You Place Your Lighting Units to Reduce Interference Risk From Other Devices?

Don’t put LED sheets near Wi-Fi routers, metal ducts, or big appliances. These can reflect or block signals, especially for IR systems. Wall-mounting at eye level works better than ceiling mounts for clear signal paths. If you need ceiling mounts, consider adding signal repeaters to boost reception.

Why Is Regular Inspection Important Even If Everything Appears Functional Today?

Over time, connectors can rust. Solder joints can crack from heat changes. Capacitors can wear out under heavy use. These small issues can lead to bigger problems later. Checking your system every six months catches these issues early, before they cause total failure.

How Should You Handle Components Like Receivers During Storage Or Transport To Avoid Damage?

Store parts in anti-static bags to prevent static damage. Don’t stack heavy items on Flexible LED Sheets, as their thin materials can bend or break. Label connectors clearly to avoid wiring mistakes when setting up again. Wrong connections, like reversed polarity, can fry the receiver instantly.

FAQs

Q1: Why does my remote work sometimes but not always, even when pointed at the LED sheet?

A: This might be from a weak battery sending faint IR signals. Bright room lights can also mask weak signals. Replace the battery and test in dim lighting to see if it helps.

Q2: Can I swap my IR remote for an RF one to get better range?

A: Only if your receiver supports RF signals. You’ll need to replace both the remote and receiver as a matching set with the same frequency and protocol.

Q3: My multimeter shows the right voltage, but nothing turns on—what’s next?

A: Use an oscilloscope or logic analyzer to check signal quality. Steady voltage doesn’t mean the dynamic signals needed for commands are working right.

4